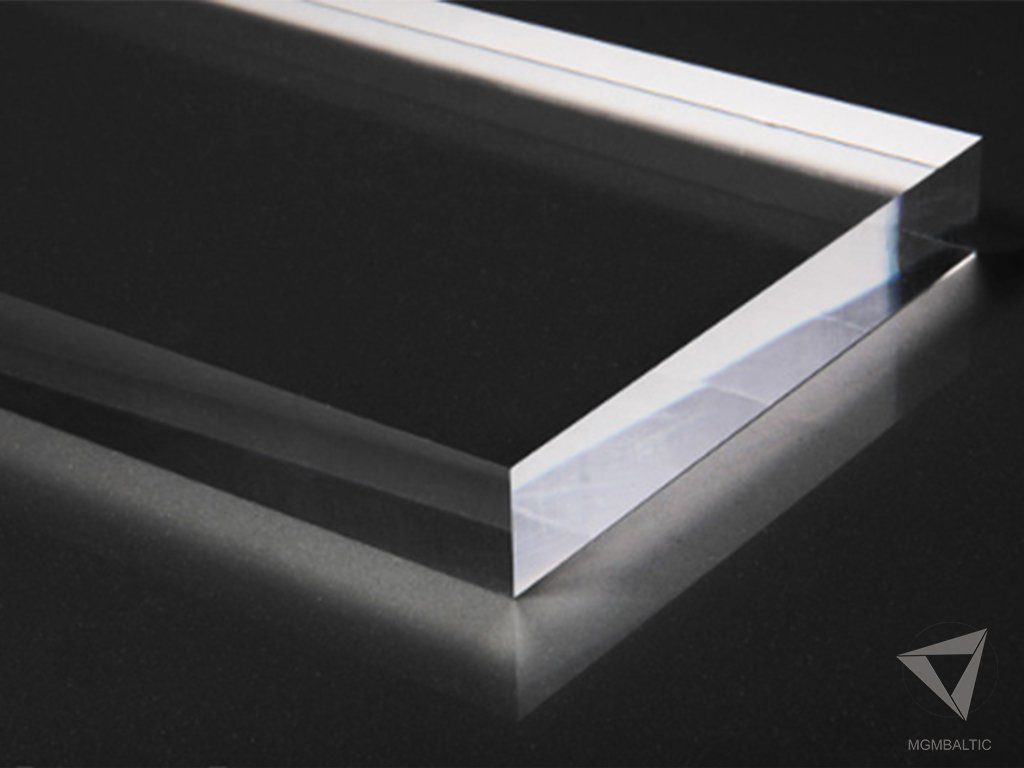

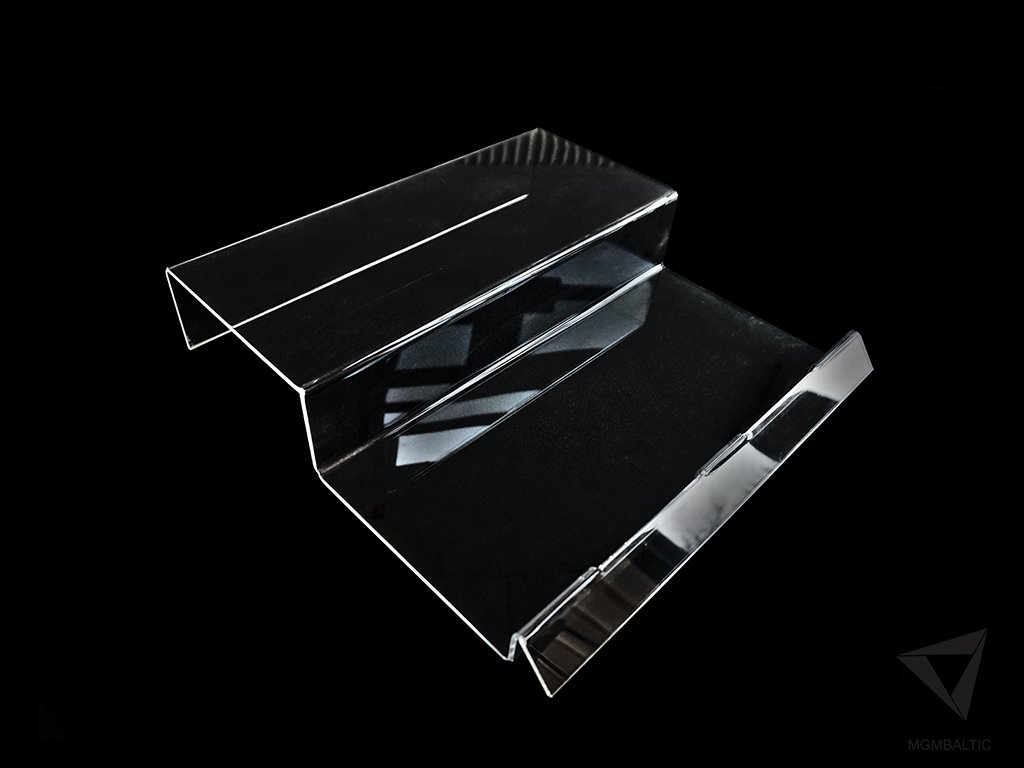

Plastic edge polishing

Edge polishing - fire, diamond, manual

Edge polishing is an important process to ensure the aesthetics, clarity and safety of plastic products. Different polishing methods can be used depending on the desired result and the material properties.

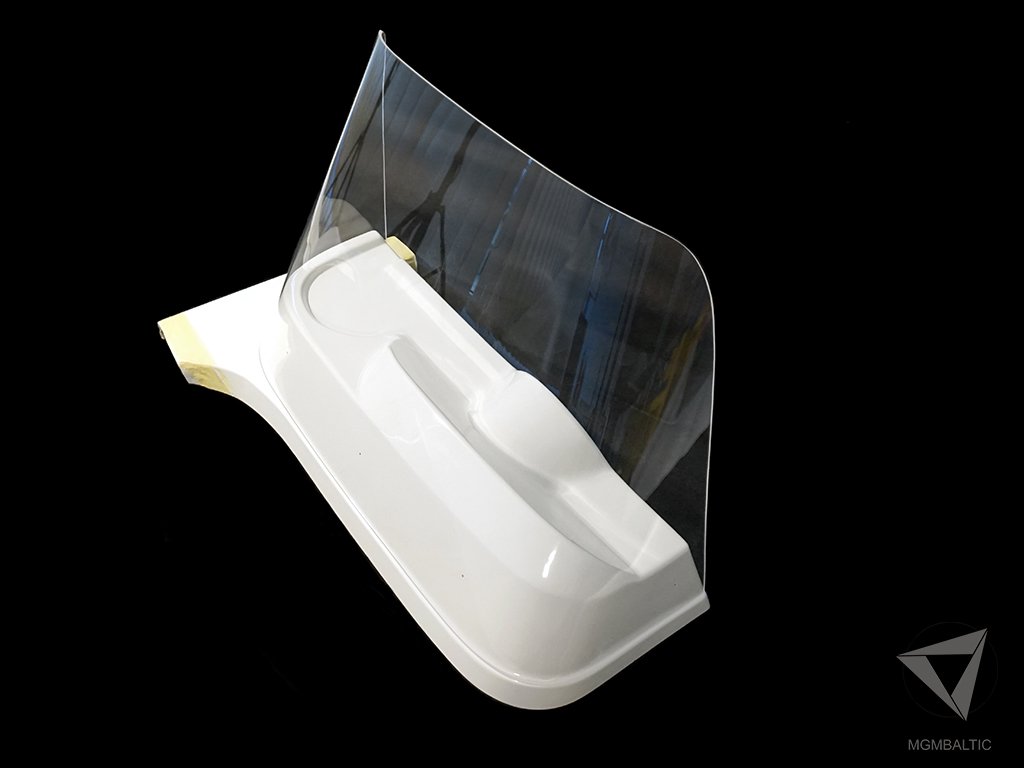

1. Fire polishing

This is a process where the edges of the plastic are exposed to a special flame that melts the surface, giving it a glossy and transparent finish.

✅ A fast and efficient method.

✅ Gives a glossy, smooth surface.

✅ Suitable for acrylic and clear plastics.

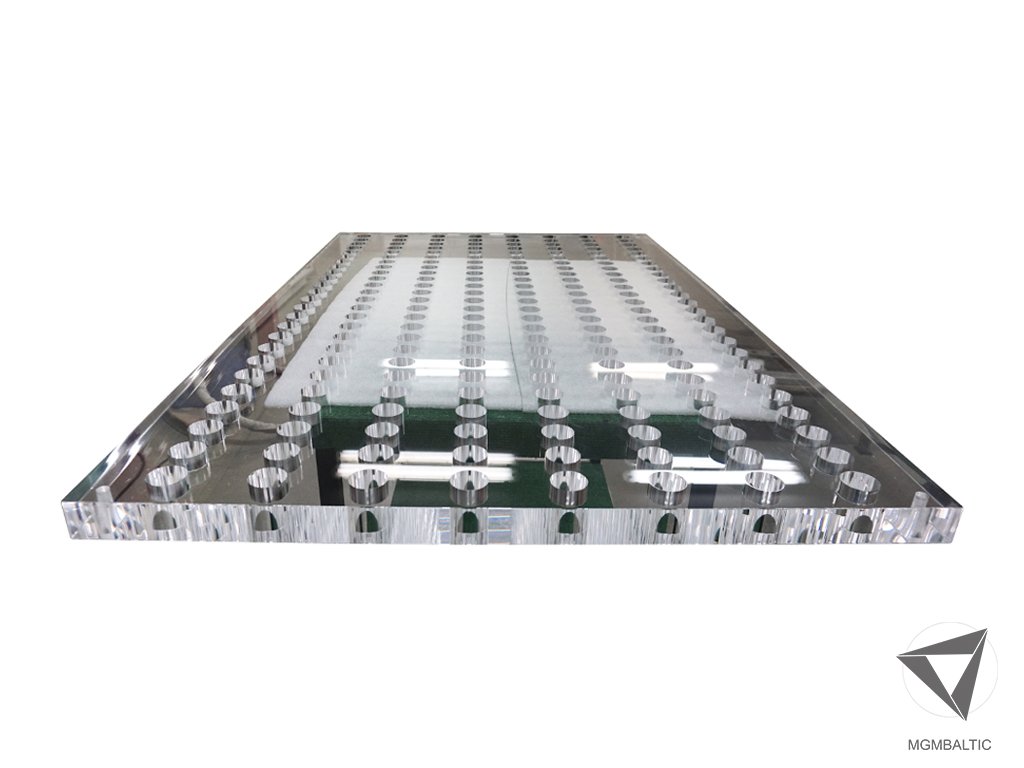

2. Diamond polishing

This is a mechanical method where the edges of the plastic are ground using diamond tools.

✅ Ensures a highly precise and uniform edge finish.

✅ Suitable for products requiring high quality and precision.

✅ Used for thick plastic panels.

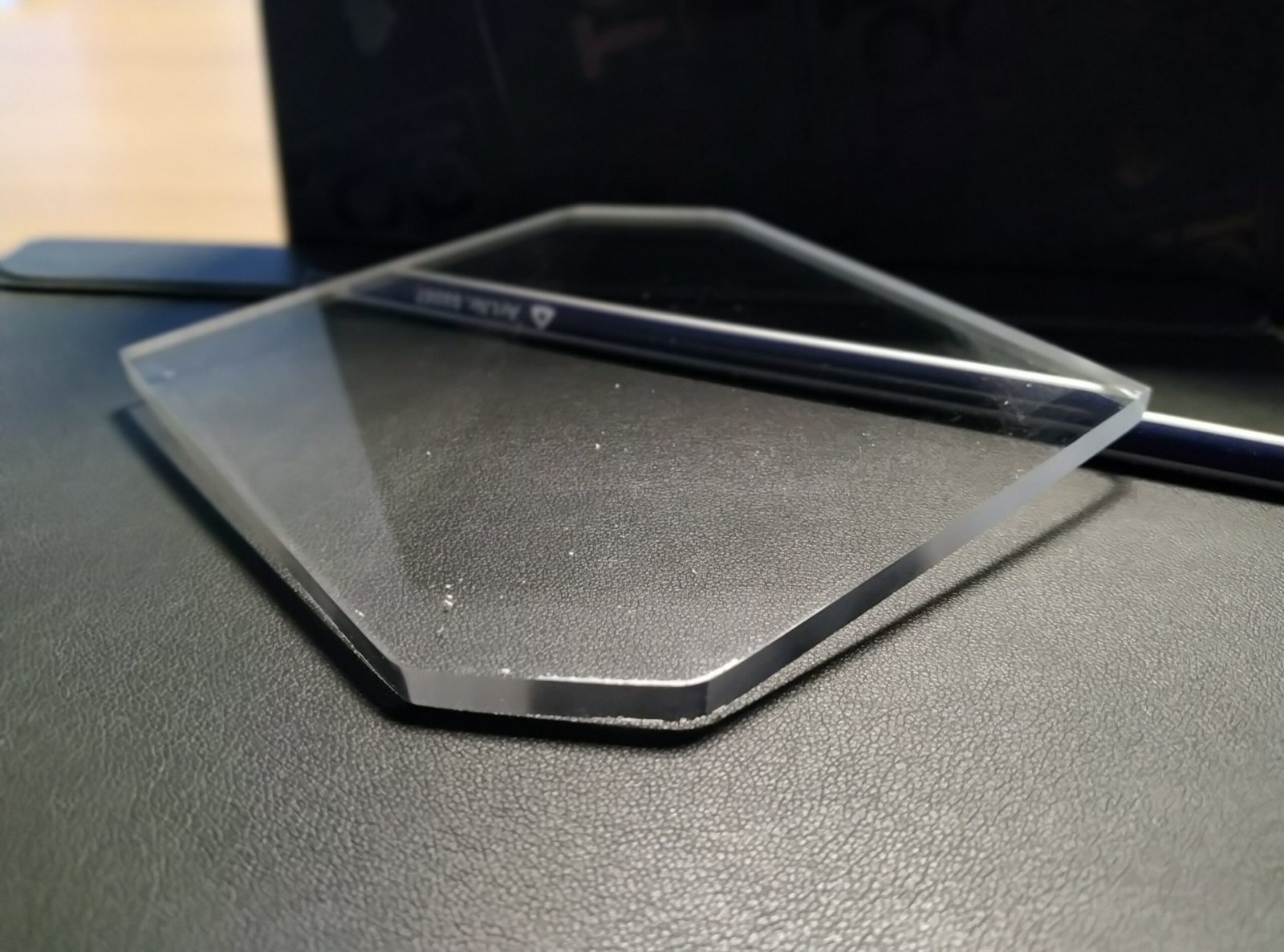

3. Manual polishing

This is a painstaking process using sandpaper, pastes and polishing tools.

✅ Suitable for small quantities and unique products.

✅ Ensures customised machining and high quality.

✅ Used for small parts and complex shapes.

Each method is chosen according to the type of product, the aesthetic requirements and the properties of the material, in order to achieve the optimum result.